Taconic to add least 12 full-time positions

On March 18, 2022, Taconic Biosciences broke ground on a new production facility, expanding the footprint at its 27.9-acre Cambridge City, IN, campus. Slated for completion in September, the 5,960-square-foot building increases capacity and will benefit the Cambridge City community by bringing new jobs to the region. As the new facility ramps up production, Taconic expects to hire at least 12 employees in operations, quality, and veterinary sciences."As our business expands, we looked to the Cambridge City location due to quality and availability of potential team members. Our employees are part of a dynamic and important industry providing valuable tools supporting drug development," said Nancy J. Sandy, chief executive officer of Taconic. "This expansion will help increase the supply of Taconic's products and services that are used by leading pharmaceutical, biotechnology and academic organizations."

Bringing More Product Closer to More Customers

"As Taconic's business grows, it's vital that we strategically align our facilities and capabilities with our customers' research facilities. With demand accelerating across the Midwest and West, it was time to boost our capacity in the region to bring more products closer to this growing customer base," Sandy added.The new building at the Cambridge City site will feature an open floor plan with improved workflow and ergonomics.

"Along with expanding our production capacity, the new building takes a more modern approach to lab animal facilities," said Alaina Luther, senior director, supply chain. The design affords Taconic staff more flexibility and enables movement through the facility while maintaining biosecurity.

Getting Up to Speed Faster

Taconic and Poynter staff come together for the Cambridge City Groundbreaking: Pictured from right to left: Chip Parsley, Director of Prefabrication Solutions, Poynter, Nathan Shinkle, Project Manager, Poynter, Nancy Sandy, CEO, Taconic, Connie Campisi, Director U.S. Commercial Production, Taconic, William Stevens, Vice President Human Resources & Organization Development, Taconic, Alaina Luther, Senior Director Supply Chain, Taconic, Keith Lehman, Manager Production, Taconic, and Jennifer King, Manager Production, Taconic.

To bring this concept to reality, Taconic partnered with Poynter, a leader in prefabricated facility solutions. Poynter is constructing the modular building offsite for assembly onsite--an approach that shortens the project timeline and enables Taconic to begin leveraging additional capacity sooner."Taconic's new facility is a unique build in Indiana and across the Midwest," said Chip Parsley, director of prefabrication solutions, Poynter. "Even at a time when supply chain constraints are delaying many construction projects, our modular approach is enabling us to deliver a completed building three to four months faster than traditional construction timelines." From design to procurement to completion, the project is expected to take only 12 to 13 months.

When it's time to expand other production sites, Taconic can leverage the new building design and modular construction approach to speed the process. "Poynter can build additional modular facilities and ship them anywhere in the world," Luther explained. "So as our customers' requirements evolve, Taconic can respond quickly by expanding capacity where it's needed most."

To learn more about this new facility and new positions, please call 1-888-TACONIC (888-822-6642) in the US, +45 70 23 04 05 in Europe, or email info@taconic.com.

About Taconic Biosciences, Inc.

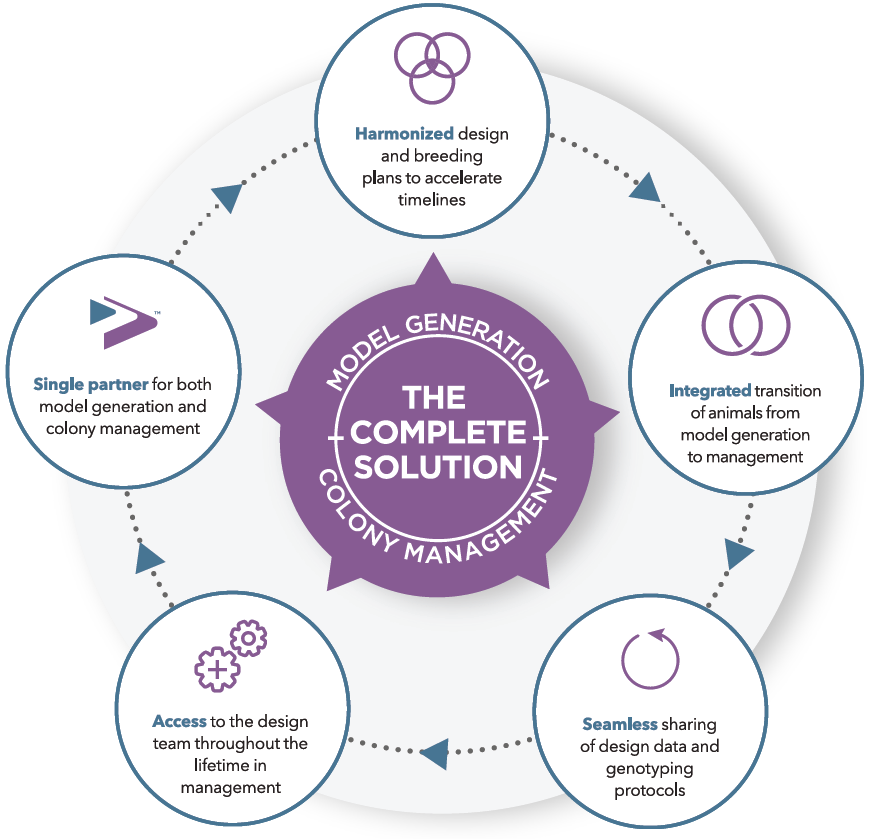

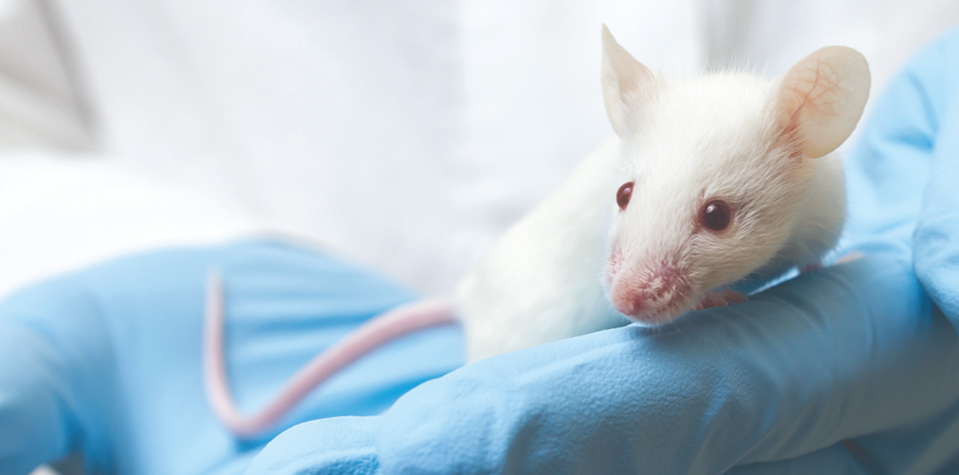

Taconic Biosciences is a fully-licensed, global leader in genetically engineered rodent models and services. Founded in 1952, Taconic provides the best animal solutions so that customers can acquire, custom-generate, breed, precondition, test, and distribute valuable research models worldwide. Specialists in genetically engineered mouse and rat models, microbiome, immuno-oncology mouse models, and integrated model design and breeding services, Taconic operates three service laboratories and six breeding facilities in the US and Europe, maintains distributor relationships in Asia and has global shipping capabilities to provide animal models almost anywhere in the world.

Taconic Biosciences is a fully-licensed, global leader in genetically engineered rodent models and services. Founded in 1952, Taconic provides the best animal solutions so that customers can acquire, custom-generate, breed, precondition, test, and distribute valuable research models worldwide. Specialists in genetically engineered mouse and rat models, microbiome, immuno-oncology mouse models, and integrated model design and breeding services, Taconic operates three service laboratories and six breeding facilities in the US and Europe, maintains distributor relationships in Asia and has global shipping capabilities to provide animal models almost anywhere in the world.

About Poynter

Poynter Prefabrication was founded in 2019 when Joseph Lansdell, president, expanded his sheet metal facility to include a space for prefabrication. As a leader in the construction industry, Joseph saw the positive impact prefabrication could have on the industry and invested in a 55,000 sf expansion making the entire shop 160,000 sf. Over the past three years, Poynter has utilized this space to help give clients custom construction in a controlled manufacturing environment. The remaining 105,00 sf of the shop is for metal fabrication, including commercial and industrial ductwork and specialty metal projects. Poynter's innovative designers and skilled craftspersons help model and fabricate metal solutions for complex and custom applications. As a full-service provider, you can work with in-house professionals from design through final project closeout.

Poynter Prefabrication was founded in 2019 when Joseph Lansdell, president, expanded his sheet metal facility to include a space for prefabrication. As a leader in the construction industry, Joseph saw the positive impact prefabrication could have on the industry and invested in a 55,000 sf expansion making the entire shop 160,000 sf. Over the past three years, Poynter has utilized this space to help give clients custom construction in a controlled manufacturing environment. The remaining 105,00 sf of the shop is for metal fabrication, including commercial and industrial ductwork and specialty metal projects. Poynter's innovative designers and skilled craftspersons help model and fabricate metal solutions for complex and custom applications. As a full-service provider, you can work with in-house professionals from design through final project closeout.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)